Home Profile

Profile  Product Range

Product Range Industries

Industries Infrastructure

Infrastructure Our Quality

Our Quality Custom Manufacturing

Custom Manufacturing Network

Network Contact Us

Contact Us Send Enquiry

Send Enquiry

Types of Pigment

In today's world, there is a large number of Pigments available. In

fact after the advent of Synthetic Pigments there has evolved various

classes of pigments that are suited to particular types of Industries.

Inorganic Pigments

Inorganic pigments are created through chemical

manufacturing rather than by grinding and washing clays or minerals taken

directly from the earth. The preparation process is also simple and consists

of the steps of washing drying, pulverizing and mixing into a formulation.

They are metallic oxides or synthetics. The following table shows the

refractive index of some of the very popular class of inorganic pigments.

| Pigment |

Refractive Index |

| TiO2 (rutile) |

2.71 |

| TiO2 (Anatase) |

2.55 |

| Antimony Oxide |

2.20 |

| Zinc Oxide |

2.01 |

| Calcium Carbonate |

1.65 |

| Fumed Silica |

1.45 |

Few Examples of inorganic pigments: lead oxide,

cobalt blue, chromium oxide, cadmium yellow, molybdate orange, and nickel

titanate. As new environmental laws are very strict about toxicity a few of

these heavy metal pigments are no longer in use.

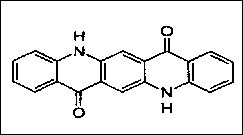

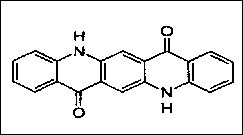

Organic Pigments-

Organic Pigments are chemically synthesized, as they are not found in

nature. They contain carbon and comes with relatively low levels of

toxicity, not providing any major environmental concern. Raw materials can

include coal tar and petroleum distillates that are transformed into

insoluble precipitates. They are used as mass colorants and are popular in

plastics, synthetic fibres and as surface coatings-paints and inks. In

recent years the organic pigments are used for hi-tech applications that

includes photo-reprographics, opto-electronic displays and optical data

storage.

Categories of Organic Pigments

Organic pigments are generally categorized into six types :

- Diazo Pigments

- Monoazo Pigments

- Acid and base dye Pigments

- Phthalocyanine Pigments

- Other polycyclic Pigments

- Quinacridone Pigments

Key features and characteristics of Organic Pigments

- Good tinctorial strength

- Cost effectiveness

- Consistency and unique shades

- Completely non-toxic

- Organic pigments shows good color strength

- Very good stability to solvents, light, heat, and weathering

- Very bright, pure, rich colors

Metallic Pigments

Metallic Pigments give bright effects, due to

this they are widely used and are a very popular category of pigments.

Metallic pigments, can be of two types aluminum and zinc.

Aluminium Pigments:

Glittering silver effects are achieved in the widest variety of different

applications by the use of various forms of aluminium pigments. They are

further divided into two categories namely leafing grade and non-leafing

grade. The aluminum pigments are produced from aluminium that has purity in

the range of 99.3-99.97%. The particle has lamellar shape with 0.1-2 um in

thickness and diameter of 0.5-200 um. These pigments founds use in

automotive topcoats.

Some of the preferred applications of Aluminium Pigments are the

following:

- As Reflective paints

- As Corrosion protection coats

- In Marine paints (covering coats)

- Chrome effect paints

- Aerosols

- Roof coatings

- In Heat-proof and highly heat-resistance paints

Zinc Pigments:

The anti-corrosive properties of zinc have been well-known for decades.

Zinc pigments represent an almost ideal combination of the active

anti-corrosive properties of the metal itself with the protective barrier

effect of leaf-shaped pigments.

Zinc Pigments come in two forms of powder and dust. Usually the zinc dust

is finer as compared to powder and is spherical in shape. The dust also has

a light coating of zinc oxide.

The following table cites some popular Zinc Pigments along with their

applications.

| Zinc Pigments |

Application |

| Zinc dust |

Chemical applications Metallurgical applications |

| Zinc phosphate |

Active ingredient in domestic cleaning products |

| Zinc oxide |

Agricultural applications

Rubber industry

Brick kilns

Ceramics |

Industrial Pigments

A few popular pigments have been given below that

have very wide uses:

- CLC Pigments

- DPP Pigments

- Ultramarine Pigments

- Effect Pigments

- Pearlescent

- Fluorescent Pigments

- Inorganic Pigments

- Natural Pigments

- Carbon Black

|

- Organic Pigments

- Organic vs Inorganic Pigments

- Mixed Metal Oxide Pigment

- Phosphorescent

- Pigment Intermediates

- Synthetic Iron Oxide Pigments

- Titanium Dioxide

- Natural Iron Oxide Pigments

|

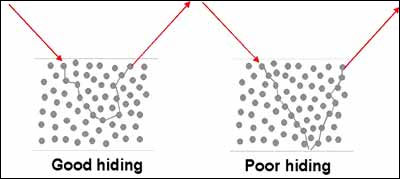

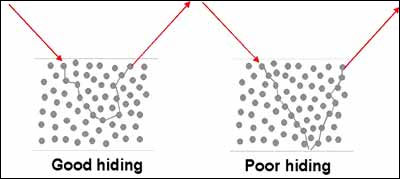

Refractive index and Classification of pigments

Pigments

are used to give color and protect the substrate. To provide color to a

material pigment should create an opacity. There is a particular limit to

the concentration of pigment particles in a coating determined by the

pigment volume concentration (PVC). This is the reason for having pigment

particles with a high refractive index.

Based on such refractive index, pigments can be divided into two categories

of hiding and extender pigments.

Hiding pigments:

These pigments possess generally refractive index values that are greater

than 1.5. Examples: titanium dioxide, zinc oxide, lithophone etc.

Extender pigments:

These pigments have refractive index values that are close to 1.5.

Examples: calcium carbonate, silica, alkali and alkaline earth metal

silicates etc.

Selection of Pigment and Binder Stability

If you are considering pigmentation of a system,

that is inherently unstable, for example an unstable binder that is to be

pigmented with Titania, the selection of the pigment is then for both

coloration and function. While formulating a colored coating, the pigment's

role should be as an UV absorber or reflector. Thus blocking UV transmission

through the binder, where degradation takes place.

Performance Criteria for commercial organic pigments

The commercial performance of organic pigments

are guided by the following capabilities:

- Coloristic performance

- Durability

- Ecological compatibility

- Tinctorial strength

- Opacity

- Resistance to heat

- Rheological behavior

High

performance organic pigments have high color strength, outstanding fastness

and weatherability properties. They find usage in specialty applications.

Home Profile

Profile

Product

Range

Product

Range Industries

Industries Infrastructure

Infrastructure Our

Quality

Our

Quality Custom

Manufacturing

Custom

Manufacturing Network

Network Contact

Us

Contact

Us Send

Enquiry

Send

Enquiry

![]() Profile

Profile ![]() Product Range

Product Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our Quality

Our Quality![]() Custom Manufacturing

Custom Manufacturing![]() Network

Network![]() Contact Us

Contact Us![]() Send Enquiry

Send Enquiry

![]()

Pigments

are used to give color and protect the substrate. To provide color to a

material pigment should create an opacity. There is a particular limit to

the concentration of pigment particles in a coating determined by the

pigment volume concentration (PVC). This is the reason for having pigment

particles with a high refractive index.

Pigments

are used to give color and protect the substrate. To provide color to a

material pigment should create an opacity. There is a particular limit to

the concentration of pigment particles in a coating determined by the

pigment volume concentration (PVC). This is the reason for having pigment

particles with a high refractive index. High

performance organic pigments have high color strength, outstanding fastness

and weatherability properties. They find usage in specialty applications.

High

performance organic pigments have high color strength, outstanding fastness

and weatherability properties. They find usage in specialty applications.![]() Profile

Profile

![]() Product

Range

Product

Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our

Quality

Our

Quality![]() Custom

Manufacturing

Custom

Manufacturing![]() Network

Network![]() Contact

Us

Contact

Us![]() Send

Enquiry

Send

Enquiry