Home Profile

Profile  Product Range

Product Range Industries

Industries Infrastructure

Infrastructure Our Quality

Our Quality Custom Manufacturing

Custom Manufacturing Network

Network Contact Us

Contact Us Send Enquiry

Send Enquiry

Dye House

Dye House is a building in which dyeing is carried on.

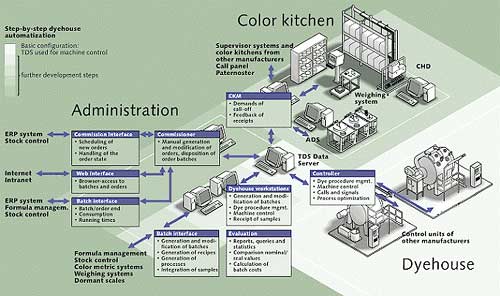

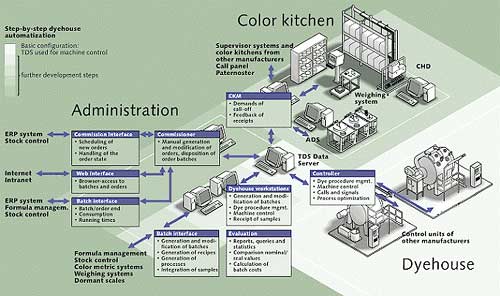

For improving quality and fast turn arounds, there is a need of fully

integrated dye house network that comprises of a vast range of automated

system components properly synchronized to each other. With the proper

integration of dyeing equipment into a sound organized network, it is quite

obvious that the dyehouses can give away its valuable resources very

cheaply.

A typical Dye house network should be equipped with the machines that are

capable of performing a number of operations like dyeing, heat setting,

compacting, stentering, hydro-extraction, brushing and washing etc. Another

vital task is the control of the system. Although every single device from

the color kitchen to dyeing machines these days are PC-controlled, however

modern dye houses prefer to employ a Dye house automation system.

Dye house automation system ensures that the machines are able to

synchronize with each other and can optimise their capacities. Apart from

this the automation system facilitates linking of the order management with

the necessary machine control units. This helps to complete a fully

integrated dye house network. The diagram that follows next gives a perfect

example of Dye house that is complete in every respect. Most modern dye

houses are today following the concept of totally networked Dye House.

Benchmarks of a Dye House

A perfect dye house should meet the following

criteria, that are given below:

A perfect dye house should meet the following criteria, that are given

below: Computer aided Dyeing system- By implementing a Computer aided Dyeing

system it has been possible to cut down on both costs and time. For example

it has been found that by using the system there has been reduction in the

acrylic dyeing batch time by at least 30 percent.

Modern laboratories- New formulas are first tried in the lab before

implementing in production. If there is closer liquor ratio agreement

between the production and laboratory, better would be the final result.

Package preparation- Latest stainless steel spacer should be used for

holding the shape of package ends. This allows for smooth unwinding. Though

backwinding to paper cones along with intermediate lubrication is more in

vogue, but that costs money and time. Dyers must master new ways to bypass

the idea of backwinding.

Package handling- Increasingly the dye houses are insisting on the

technology of robotic package handling. Use of Robotics demands uniformity.

Robots need the packages to be placed in a specific location.

Quality- In today's fiercely competitive market, if a manufacturer doesn't

have a consistent quality, probably they just can't stay put in business.

Therefore a manufacturer must insist on receiving only quality and genuine

products from suppliers. In fact adhering to different International quality

standards that has written down procedures and manuals is now more than just

a norm. There are now various information technology companies that are into

the field of operations management. If they are called for and allowed to

work on a program at a dye house and follows up it through the completion,

then a dye house will be equipped with a totally integrated data base

system. This will offer solutions in every sphere of operations like

manufacturing, production, financial, forecasting, planning, scheduling and

delivery.

Challenges of globalisation- Over the years the supply of material has

changed. Today suppliers are challenged from across globe with products of

superior quality, and low cost. For example yarn suppliers continues to

search for non-branded suppliers of polyester and acrylic for replacing more

costlier brand names. Today's mantra is innovate or perish.

Savings in energy- Saving in energy, chemicals and water is now vital for

survival of any dye house. Machine vendors are now constantly redesigning

dye machines that has the lowest liquid to goods ratio. For example a high

pressure dyeing machine consumes much less water for processing. The liquid

to goods ratio being 1:5 (i.e. to process 1 kilogram of fabric, five litres

of water are used) now compare this to traditional units that are fitted

with conventional winches whose water to liquid ratio is in the range of

1:15 or even sometimes 1:20. Survival for such dye houses is impossible.

Maintenance- It is a general tendency to view maintenance time as an

opportunity lost to manufacture dyed sales yarn. Preventive maintenance is

clearly less expensive than unscheduled halt and a spoiled dyeing.

Home Profile

Profile

Product

Range

Product

Range Industries

Industries Infrastructure

Infrastructure Our

Quality

Our

Quality Custom

Manufacturing

Custom

Manufacturing Network

Network Contact

Us

Contact

Us Send

Enquiry

Send

Enquiry

![]() Profile

Profile ![]() Product Range

Product Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our Quality

Our Quality![]() Custom Manufacturing

Custom Manufacturing![]() Network

Network![]() Contact Us

Contact Us![]() Send Enquiry

Send Enquiry

![]() Profile

Profile

![]() Product

Range

Product

Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our

Quality

Our

Quality![]() Custom

Manufacturing

Custom

Manufacturing![]() Network

Network![]() Contact

Us

Contact

Us![]() Send

Enquiry

Send

Enquiry